JX1200 Automatic corrugated box folding gluing machine

Big format corrugated box folding and gluing always been a serious problem for most of printing and packaging companies. Suzhou juxin has engaged into corrugated box folding and gluing industry more than ten years and get the best solution for that.

Brief introduction:

Big format automatic corrugated box folding gluing machine always been a serious problem for most of printing and packaging companies. Suzhou juxin has engaged into corrugated box folding and gluing industry more than ten years and get the best solution for that.

Description of Automatic corrugated box folding gluing machine

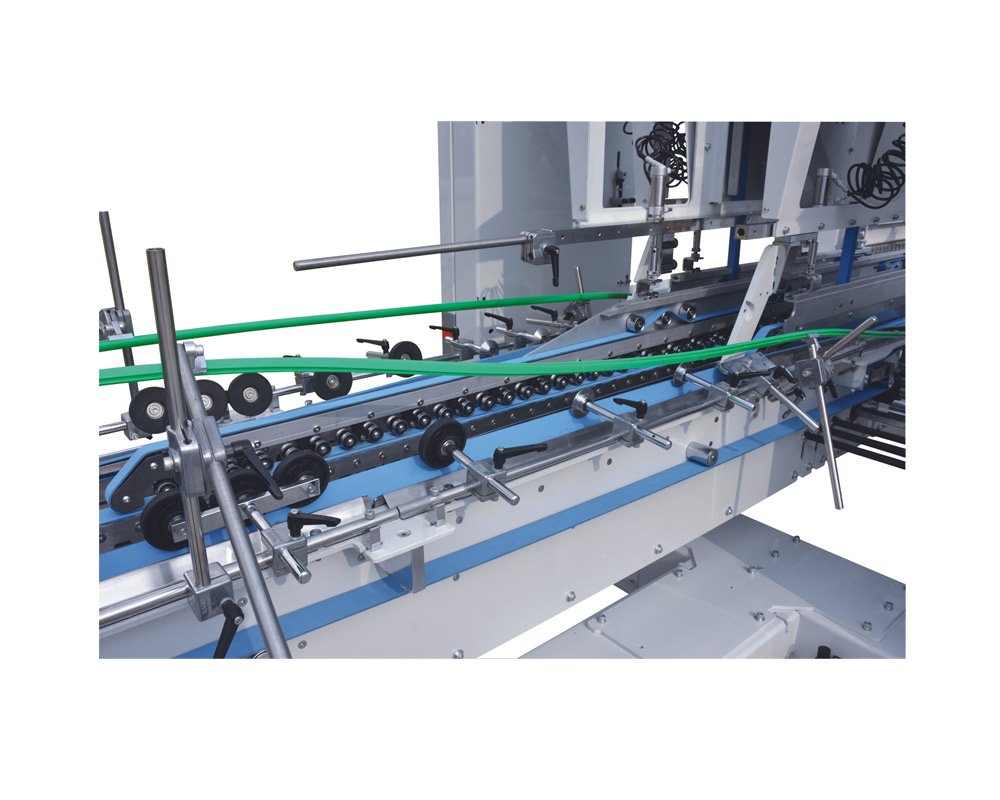

JX1200 automatic corrugated box folding and gluing machine adopts a special design portal frame. it has portal frame in each unit to protect the operator and sheet, supported the convenience operation. The mental of this machine are special harden ones to ensure the best production efficiency.

FEEDER

- Adopt high strength special vibration motor, only make the connection part through vibration feeding paper more smooth and stable.

- Independent transmission with low noise, with the front adjusting wheel operating at high and low speed, accurate transmission of paper, to reach the highest capacity.

- The paper knife and the left and right regulating fixed rod, up and down in a pneumatic way, the operation is powerful. Add air pressure device to the paper knife to make the paper more smooth with moderate pressure.

ALIGNMENT

◆Equipped with automatic correction device, to repair the paper skew phenomenon, to ensure the accurate delivery of paper.

PRE-FOLDING SECTION

◆ All cartons can be pre-folded at high speed of 180°, regardless of material.

◆ The prefolding unit that perfectly folds the edge of the pasting box.

◆ Extra wide lower left belt ensures no imprinting on the box.

◆ Flat after high-speed folding.

◆ The upper left transmitter can be lifted to make the operation more flexible.

LOCK BOTTOM SECTION

- Equipped with lock bottom combination adjustment mechanism, ideal design, quick and easy operation, coupled with high rigid spring hook seat to stabilize hook bottom operation.

- Modular design of the lock bottom unit, significantly reduce the adjustment time during the conversion operation, improve the installation and conversion time of accessories.

- Equipped with 4 sets of high elastic lock seat and lock bottom box module.

LOWER GLUING TANK

◆ Lower gluing tank increases capacity design, high-speed no glue, no glue leakage, large glue bottle, can be used for a long time.

FOLDING SECTION

- Equipped with belt transmission, can effectively ensure the parallel alignment of folded cartons

- It can be adjusted in line with various types of operation, fast and convenient, so that the box can be closed accurately.

- It has the middle up and down transmission module, which can synchronize or fold the carton alternately.`

TRANSFER SECTION

- The upper pressure bar can adjust the pressure with the thickness of the carton to make the carton moderately pressurized. For the use of A and B tiles, add the stacking and patting device to ensure the accurate paste of the carton. After the setting of the spray kick mark, it can be automatically tracked regardless of the speed, and there is no need to reset because of the speed change。

CONVEYOR

- Pneumatic pressure, independent speed control pressure, carton can do moderate pressure, and make the finished product pressure perfect.

- The front side can be matched with stacking and leveling devices for proper swing up and down.

4/6 Corner Function

- All types and most sizes of 4/6 corner boxes can be quickly set up.

- the inclined frame according to the page size of the paper box adjustable.

- 45 degrees guide plate, suitable for all the size of the paper box.

- modular folding hook running track, high speed and high quality production.

Electrical and drive systems

- Schneider brand inverter is used to realize synchronous speed regulation of the main engine, making the speed change, adjustment, stability and reliability.

- Humanized design of hd touch screen, fully consider the operator’s convenience.

- Schneider brand PLC is adopted, and a number of safety protection devices are added, making the operation of the machine more safe and reliable.

- Control panel, layout more reasonable, icon prompt, simple and easy to understand with remote control switch, make the operation more convenient.

Specification:

| Main motor | Paperboard | Corrugated | Max linear speed | Weight | Machine size |

| 20KW | 200-800gsm | Flute E.N.F | 350m/min | 13500KG | 17800*1870*2100mm |

| Total power | Power supply | Container | |||

| 30KW | 380V AC3F 50Hz | 40GP+40GP | |||

Paper size:

Max 1200×800 mm Min 400×200 mm

Application

automatic corrugated board box folder gluer machine is particularly model for the clients who has special carton board or corrugated box job, such as TV box, furniture box, house applications box and other kinds of logistic box. Which required the box much be hard and solid, difficult to break. We also have bigger size such as JX1450 and JX1700 to meet your more demands.

Warranty:

Warranty is one year. Warranty will be not valid if the machine is subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts to customers by free. And we will make service for machine whole life.

As a top manufacturer of automatic corrugated box folder gluer in china, suzhou juxin mechanical technology company is doing the great job to achieve the aim of using minimum cost to make the best corrugated box. When the fully automatic folder guler for courrgated box machine comes out, it has been bought out in one month.