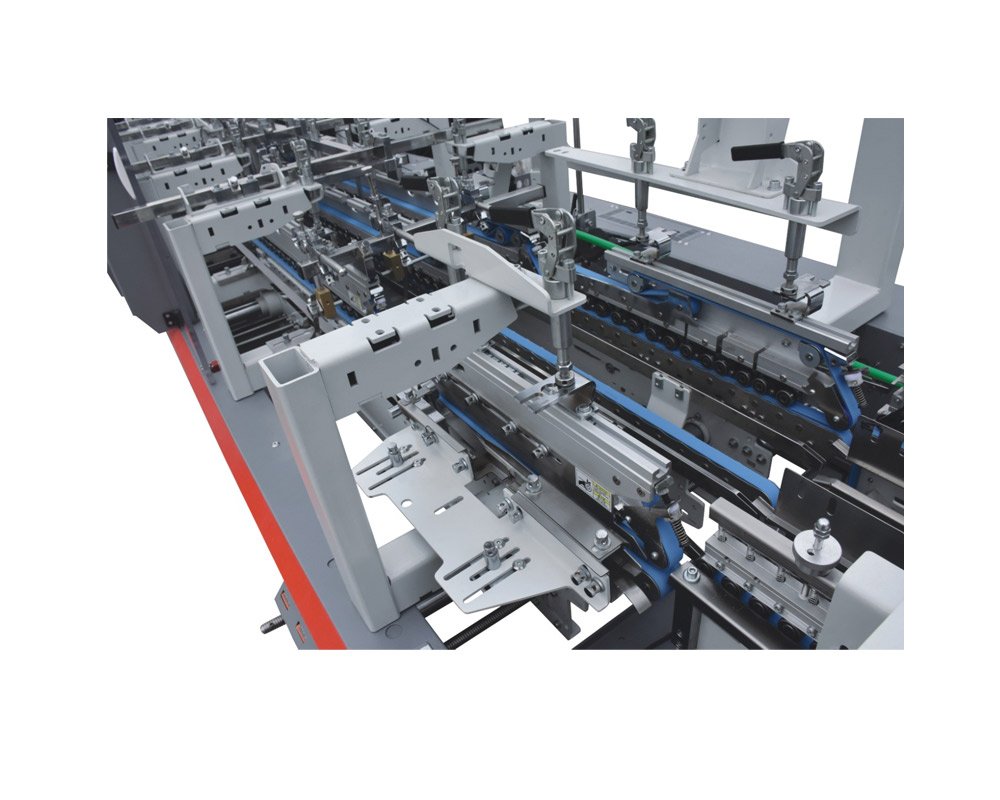

JX1100 Fully automatic folding gluing machine

Fully automatic folder gluer is a machine that folds unfinished boxes and glues them with a cold gluing wheel or the spray gluing system.Our machine(JX1100C) can make 4/6 corner boxes in best performance.It is composed of feeding device, pre-folding device, 4/6 corners device, delivery device, and pressing device.

Brief introduction:

Fully automatic folding gluing machineis a machine that folds unfinished boxes and glues them with a cold gluing wheel or the spray gluing system.Our machine(JX1100C) can make 4/6 corner boxes in best performance.It is composed of feeding device, pre-folding device, 4/6 corners device, delivery device, and pressing device.

Description

- Fully automatic folding gluing machine which can automatically complete the top folding and middle folding of the carton, and at the same time complete the tape bonding of the upper and lower parts, saving labor and time.

- Wide application range, can be used for different sizes of cartons, quick and easy to adjust.

- Fully automatic carton folder gluer works stable and reliable, packaging effect is firm, beautiful.

- Our fully automatic folder gluer is not only easy to operate but also easy to repair.

- Automatically correct the straight angle of the carton, perform 180 degree correction, and effe

ctively correct when the carton has a fork tail phenomenon.

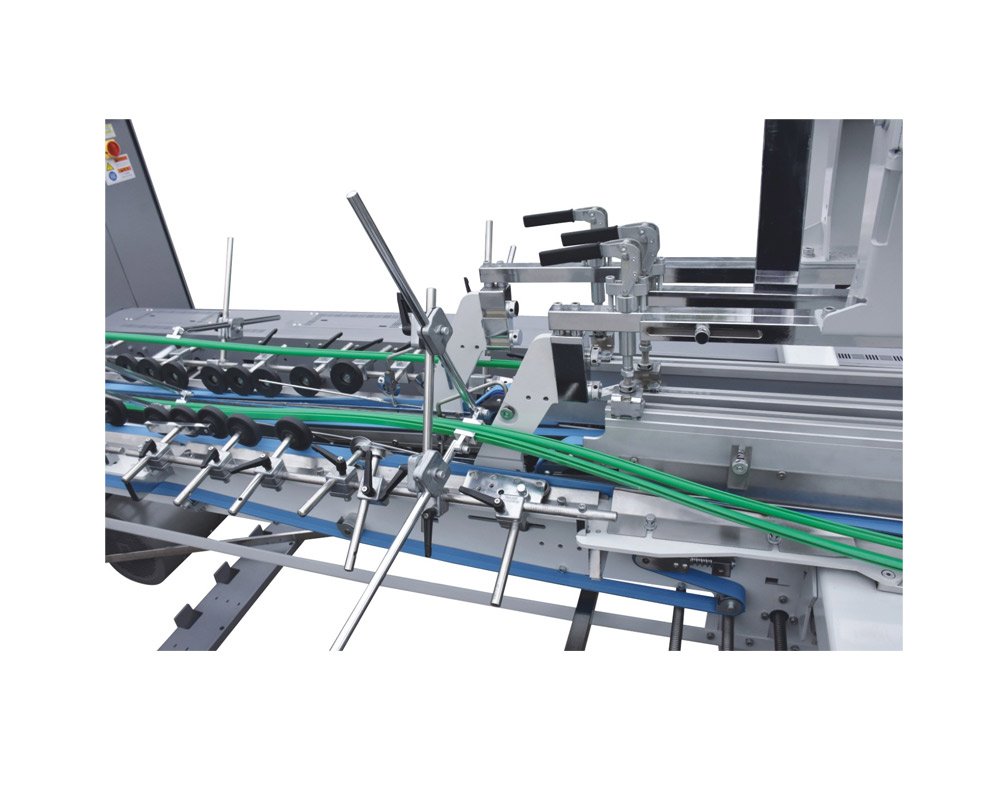

Feeder

- MIKI-pulley infinite speed variator 1/set.

- Independent adjust feeding belt, ensure the smoothly paper feeding.1set/6pcs,size: 1026*30*8mm

- Independent motor, inverter adjust speed, effectively ensure the balance of paper spacing.

- Paper carry rod with high performance Taiwan-made vibrating motor.

- Air feeding device.(optional)

Alignment unit

- Aligning the askew paper wihch from feeder, make sure the paper running in straight line.

- Alignment unit can be adjusted up and down, suitbale for different thickness paper stably.

- correct the paper, avoiding the paper going to two sides.

Two belts: 2145*34*4mm

Pre-folding unit

- 3 plate conveyor belt structure, segmenting left and right upper belt plate

- can be adjusted according t

o product demand, fast and efficient.

- effectively complete the pre-folding of carton 1 and 3 folding lines, and optimize the final molding effect.

- three long top courier in this section, 180 degree folding could be preformed.

Nitta belts :1 set /5pcs

specifications:1985*24*3mm-2pcs 3375*24*3mm-2pcs

5000*44*3mm-1pcs 5000*24*3mm-2pcs 4755*30*4mm-1pcs

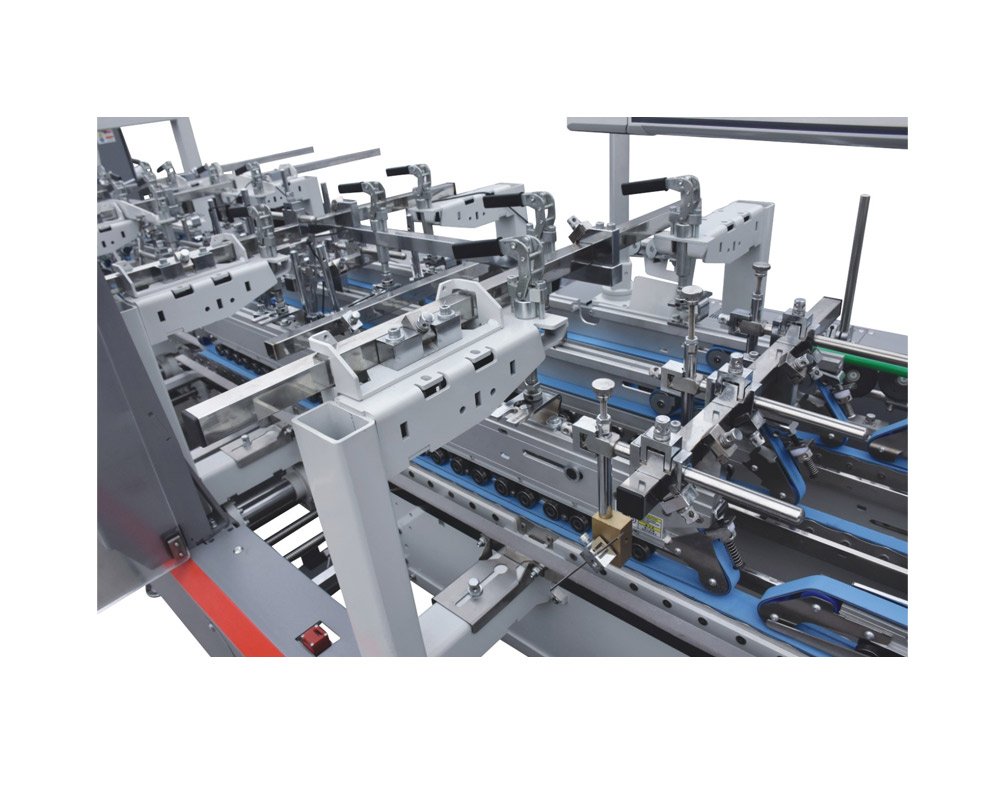

Crash-lock unit

- 3 plate conveyor belt board structure, segmental upper belt board function is the same as the prefoldin

g part, eliminate the problems in the production of special-shaped box products effectively.

- The upper and middle belt board is detachable, depending on product requirements for disassembly and debugging.

- Nitta belts 1set /9 pcs

specification: 1985*24*3mm-2pcs 3375*24*3mm-1pcs

1780*24*3mm-2pcs 3450*24*4mm- 3pcs

3610*30*4mm-1pcs Safety door (Optional)

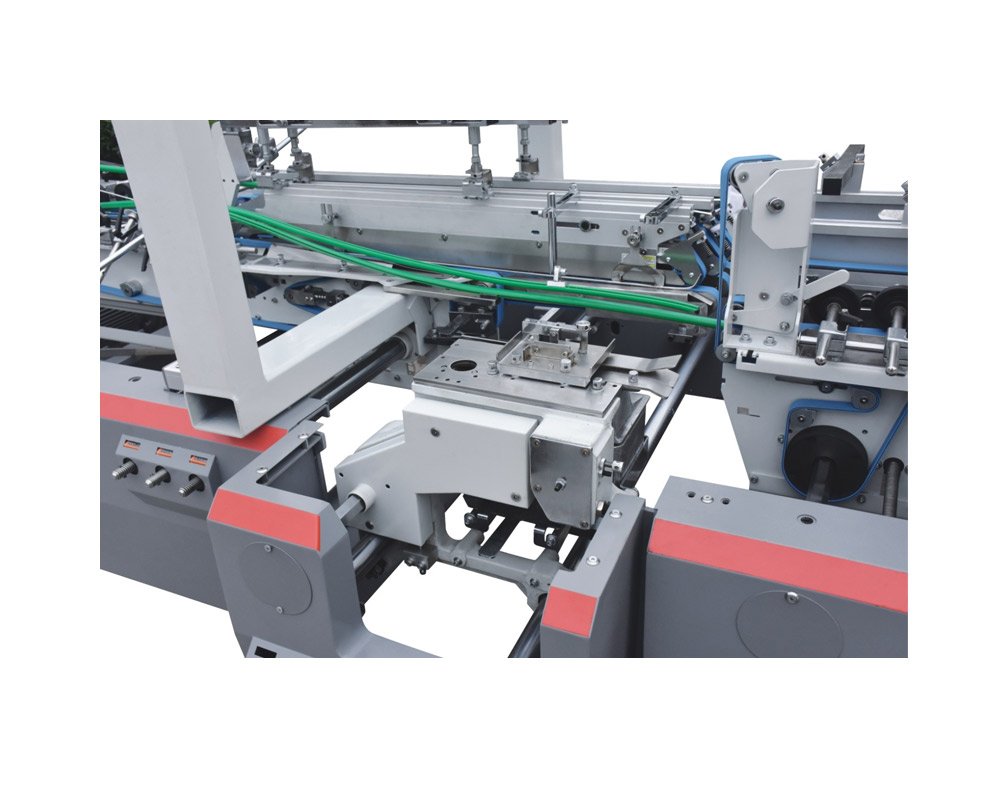

Gluing unit

- The mechanical lower pasting cylinder is designed with separate type of rubber wheel and rubber cyli

- nder, high speed, easy to clean and maintain.

- Crashlock, 4/6 corner box ,etc need to equip eletrical spray guns. (recommend 3 or moreguns)

- width of gluing wheel 4MM (standard), other width could be customized

Folding unit

- 3 plate conveyor belt board structure.

The left and right outside folding belt speed can be adjusted independently to ensure the molding accuracy.

- Wide box type can be matched with middle upper and lower belt plate to ensure stable transportation.

- Nitta belts 1set /8pcs

- specification: 2785*24*3mm-1pcs 4565*24*3mm-1pcs 3175*24*3mm-1pcs 7320*34*4mm-3pcs 7520*35*4mm-2pcs

Pressing unit

- Independend inverter adjust speed, proportional linkage to main engine under automatic model, adjusting separately with the same speed as the main engine under manual.

- Upper and lower belt telescopic adjustment is simple and easy to operate.

- Equipped with high speed electronic kick counter.

Transportationunit

- In automatic mode, the paper box spacing is set. The pressure belt speed is connected with the belt speed of the main engine in proportion. When photoelectric monitoring the paper box, the leather moves.

- In manual mode, the pressure belt is delivered at a constant speed, which is not affected by the machine speed.

- The pressure part adopts the pressure type pressing, the

pressure control is more accurate, the product bonding effect is more guaranteed.

4/6 corner function (Optional)

- All types and most sizes of 4/6 corner boxes can be quickly set up.

- the inclined frame according to the page size of the paper box adjustable.

- 45 degrees guide plate, suitable for all the size of the paper box.

- modular folding hook running track, high speed and high quality production.

Electrical and drive systems

- Schneider brand inverter is used to realize synchronous speed regulation of the main engine, making the speed change, adjustment, stability and reliability.

- Humanized design of hd touch screen, fully consider the operator’s convenience.

- Schneider brand PLC is adopted, and a number of safety protection devices are added, making the operation of the machine more safe and reliable.

- Control panel, layout more reasonable, icon prompt, simple and easy to understand with remote control switch, make the operation more convenient.

Specification:

| Main motor | Paperboard | Corrugated | Max linear speed | Weight | Machine size |

| 11KW | 180-650gsm | Flute E.N.F | 400m/min | 5500KG | 1600×2300x1900mm |

| Total power | Power supply | Container | |||

| 26KW | 380V AC3F 50Hz | 40GP+20GP | |||

Paper size:

- straight line box W×L: max 1100×1100 mm min 90×60 mm

- lock bottom box W×L: max 1000×1100 mm min 150×60 mm

- 4 corner box W×L: max 1000×800 mm min 200×100 mm

- 6 corner box W×L: max 1000×800 mm min 250×100 mm

Application of automatic carton board folder gluer machine

automatic carton board folder gluer machine is particularly right for the clients who have big order with short time deadline cause our machine can make the folding and gluing with fast speed, we sold automatic folder gluer machine to Asia, Europe and Mid-east, and we will continue to support the machine for the whole using lifetime.

Warranty:

Warranty is one year. Warranty will be not valid if the machine is subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts to customers by free. And we will make service for machine whole life.

Suzhoiu Juxin has focused on the production and promotion on the fully automatic carton folding gluing machine project for years. We are working on the possibility to make the machine more easy to operate and understand.

ctively correct when the carton has a fork tail phenomenon.

ctively correct when the carton has a fork tail phenomenon.

o product demand, fast and efficient.

o product demand, fast and efficient. g part, eliminate the problems in the production of special-shaped box products effectively.

g part, eliminate the problems in the production of special-shaped box products effectively.

The left and right outside folding belt speed can be adjusted independently to ensure the molding accuracy.

The left and right outside folding belt speed can be adjusted independently to ensure the molding accuracy.

pressure control is more accurate, the product bonding effect is more guaranteed.

pressure control is more accurate, the product bonding effect is more guaranteed.